I have used the method described here http: The original artwork, by resizing it a little bigger seem to accomplish and make up for the rotary settings for me. Well I've been doing that for almost 2 days, I figured there was some kind of mathematical sum or function to come up with what number to put into the "circle pulse" box. I am asking what the actual size is on the object when you attempt to engrave it using your settings. So fast it would never be where you actually started, so if you wanted to run something twice you wouldn't be able to do it as it never went back to the actual "start" position Sorry I can't remember which one, but you can mess with the settings to experiment, just don't forget what you changed and from what changed. I had my image scaled to size, which I myself couldn't get it to work properly, so I rescaled my original image a little larger, ran samples till I hit my mark perfectly, now the downside for me was I had everything tweaked right on as I was doing a graduated cylinder so the degree marks had to be perfect, which I finally got it, but for some reason I couldn't get a "clean" white-ish mark on red anodized, just wouldn't cut through it no matter what settings I had.

| Uploader: | Vudogal |

| Date Added: | 2 October 2018 |

| File Size: | 66.37 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 28377 |

| Price: | Free* [*Free Regsitration Required] |

So far everything is like at least 4 times bigger with the correct diameter imputed I have a graduated dial job that I am trying to get running with the fixture.

I have it laid out in Draw a total of What is the height of the image in Laserworks? I think our rollers maybe lift the piece up when going in one direction on the y axis and then push it down giving more friction in the other, a bit like a front wheel drive having more traction whilst reversing ; If we use the convention x by y for sizes, then if you wanted What is the diameter or circumference of the object?

I did set it up for a titanium job to engrave a line "around" the part with Cermark and that worked awesome.

If 6.00 cannot sacrifice an object of about Right now I am lost and ready to start from the beginning again! I haven't used the fixture since but I did leave all the settings alone.

Yes I did get it to function and I got super busy as I was going to update my progress!!

Once you scale it rdczm, your further problem is slip and accuracy, related to mounting your narrow piece, but you need to be able to get say a 20mm square in your software predictably being 20mm on a real wine bottle label first.

I'll keep an eye open for further updates.

Rdcam 6.0.44 social advice

Morning all, I've been messing around with trying to get my rotary fixture to agree to engrave properly haha! Any help to ease my pain would be welcomed!!!

I do appreciate the time and the help, thank you John!! I tried to solve this equation by comparing medians in different diameters but I still haven't been able to stablish a pattern.

The crucial bit of info we are missing to work this out is 60 combination of intended vs actual height. I should have some time yet today to mess around with the fixture and settings as I had to take myself away from it for a couple days! I did what was described here http: John, again thank you! There is nothing magical about using the rotary axis, it is just a motor that is usually the same or similar to that driving your usual axes but through gearing or roller size it moves a different distance which needs correction by the circle pulse setting.

It seems to me that even though you size the graphic in Draw, when putting it over into the Laserworks then to the engraver everything changes.

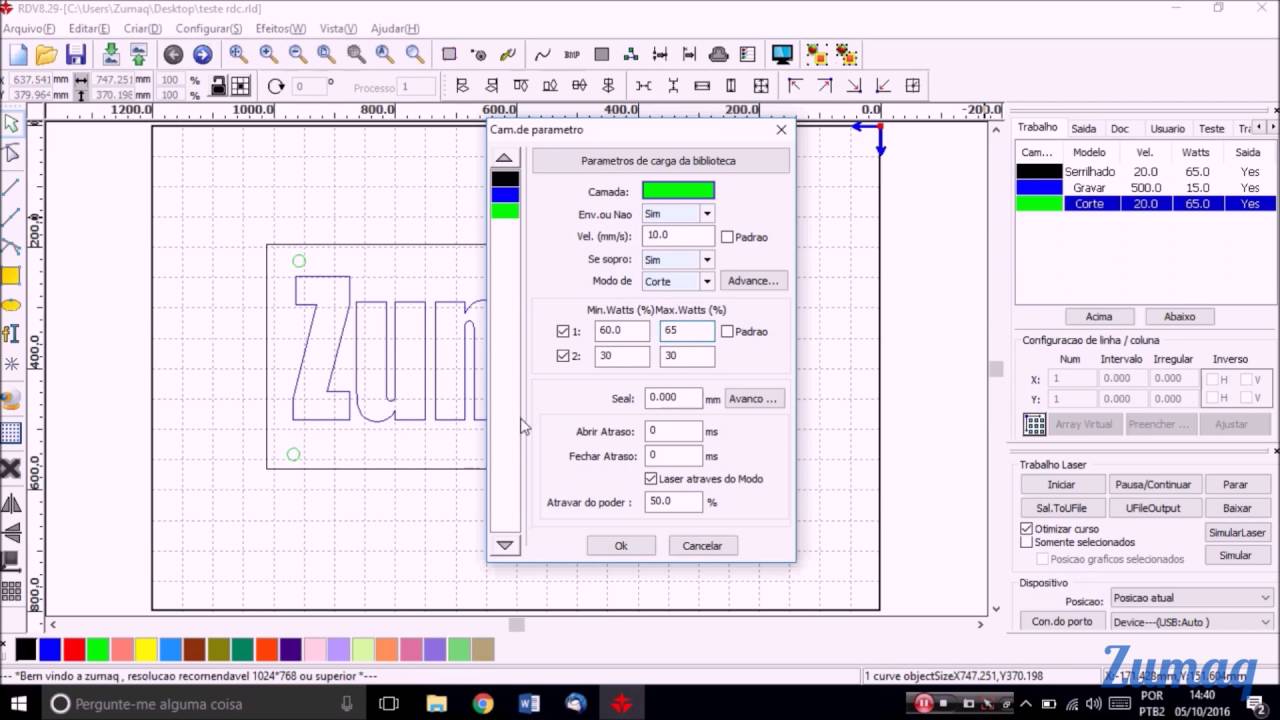

Troubleshooting - RDCAM problems with dxf librecad

I would do ddcam same and just toss the fixture aside but I do have a few jobs that I can use it for and maybe two more in the future.

Soon as I get some free time I will be working on figuring something out I can live with.

I used calipers to measure the wine bottle, how do I determine slippage and if so how do I fix that? What is the height of the image in Draw?

RDCAM Download (Free)

In fact, I recall having a discussion with Shenhui Tech support and they specifically mentioned not using the enable rotary engrave option and agreed with the method described in the link. There is no reason that this should not be a simple linear equation, but when you are deep in a rdfam it may be difficult to see the wood from the trees. Hi John, I guess I should explain myself clearer as it's not too big of a problem to engrave something on glass etc.

Thank you for taking the time!!! The same ratio doesn't seem to work for every diameter and the formula in the help section of laserworks doesnt seem to help, the translation from chinese to english seems quite sketchy.

RDCAM 6.0.44 problems with dxf librecad

Good luck as it really shouldn't be this complicated rrcam get something like this to run half-way decent!! Again thank you John! At that point I had scrap issues along with time issues and had to tear the job down and run them manually on my YAG. We did the testing and setup and never used the rotary again!

Комментариев нет:

Отправить комментарий